Sandblasting Services for Metal Surfaces

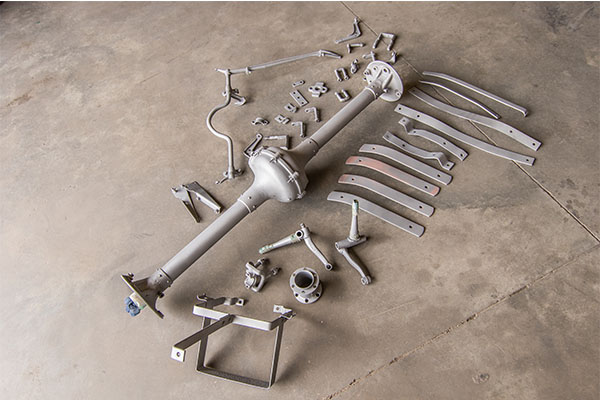

Ensure a quick turnaround for your next project — rely on Quality Powder Coating. Our sandblasting services in Utah successfully remove old paint, rust and other impurities from metal surfaces. From car parts to metal furniture, our sandblasters provide the optimum protection your metal surfaces need for a long-lasting finish.

We sandblast before powder coating your metal surfaces because it helps prepare metalwork for high adhesion with the powder coat. Our abrasive sandblasting booth is 28′ by 15′, allowing us to sandblast any size project.

Sandblasting to “White Finish”

-Removes any paint, corrosion, dirt, oil, and rust from the surface with abrasive starblast media.

-Creates a velvet surface, cleans hard to reach surfaces and prepares the metal for priming and powder coating.

At Quality Powder Coating we offer a one year guarantee on any projects that are Sandblasted, Primed, and Powder Coated

Why Sandblast Before Powder Coating?

Sandblasting prepares the metal to be powder coated by removing all impurities. It also creates a profile, or thousands of microscopic ridges and valleys. This profile allows for the small molecule epoxy primer to melt deep into the valleys of the metal creating a mechanical bond from the metal to the “Super Durable” powder coat. This is the best coating on the market creating the longest lasting finish on the market. The process of sandblasting, epoxy priming and powder coating has been tested by unbiased labs and has shown long-lasting hold against rust, corrosion, and salt-spray.

Choose Utah’s Quality Powder Coating

At Quality Powder Coating we are dedicated to our customers and stand behind our services one hundred percent. We have been in the business for nearly a decade and hold a high standard for our sandblasting services. Each project is inspected before moving on to powder coating to make sure that the metal has been sandblasted to a clean “White Metal Finish.” Our sandblasters are extensively trained and qualified to produce the cleanest and most precise surfaces.